|

WEEK THREE

|

|

|

|

| Monday arrived... | ...Still no steel... |

|

|

| ...Until late Tuesday afternoon |

Wednesday morning the work started. The base plates were aligned, leveled and then welded together. |

|

|

| The equal angle sections were cut to length and welded at two foot intervals. These form the bracing for the hull side plates. | The first side plate welded in position . |

|

|

| The second side plate and bracing bars welded in place along with the 11' x 22" swim cut and fixed to the centre of the boat (this is where the stern tube will be welded for the prop shaft to travel through the hull). | The first left hand side plate welded in place and the engine room floor bracing bars ready to accept the engine. |

|

|

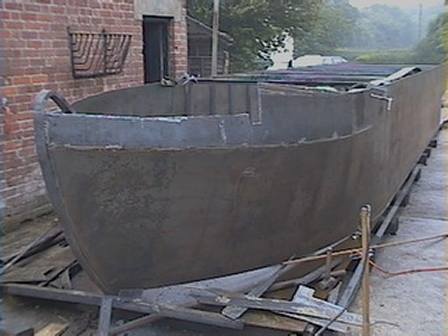

| Both hull sides completed, aft swims joined after engine installation. This gives a clearer view of the drive train layout. The prop-shaft will come from the engine, though the hull at the swim join to meet the propeller. | The front of the boat. A single cylinder Lister generator (240 volt, 3 kW) can just be seen inside the hull. The protruding plates will be bent in to meet a bent rectangular post, the bow stem. |

|

|

| Bending the bow stem (the easy way) by reversing a digger over it. The bow stem can just be made out as the blue ended rectangle under the rear wheel. | The stem post securely welded in position a the very front of the boat. The rear straight edge of the post to be cut off later. |

|

|

| The first bow side clamped in position, ready to be welded. | Both bow sides welded in place and the top of the bow also in place to define the bow shape. |

|

|

| The painted engine roughly in place in the engine room. | Hull with gunwales in place almost ready for the cabin sides. |

|

|

| Temporary cabin side support (one of many) to stop the base of the cabin sliding off the gunwales when raised into position, | First cabin side in place, propped on the inside to allow the other side to be raised, supported and roof ties to be welded on. |

|

|

| Front section of the cabin propped in place, a few of the roof ties welded onto the one side and resting on the other, which needs to be pushed out at the top. | First section of the cabin complete, all tack welded. It just needs seam welding and the roof on to finish. |